QUESTION: What is a light gauge steel (LGS) and prefabricated building?

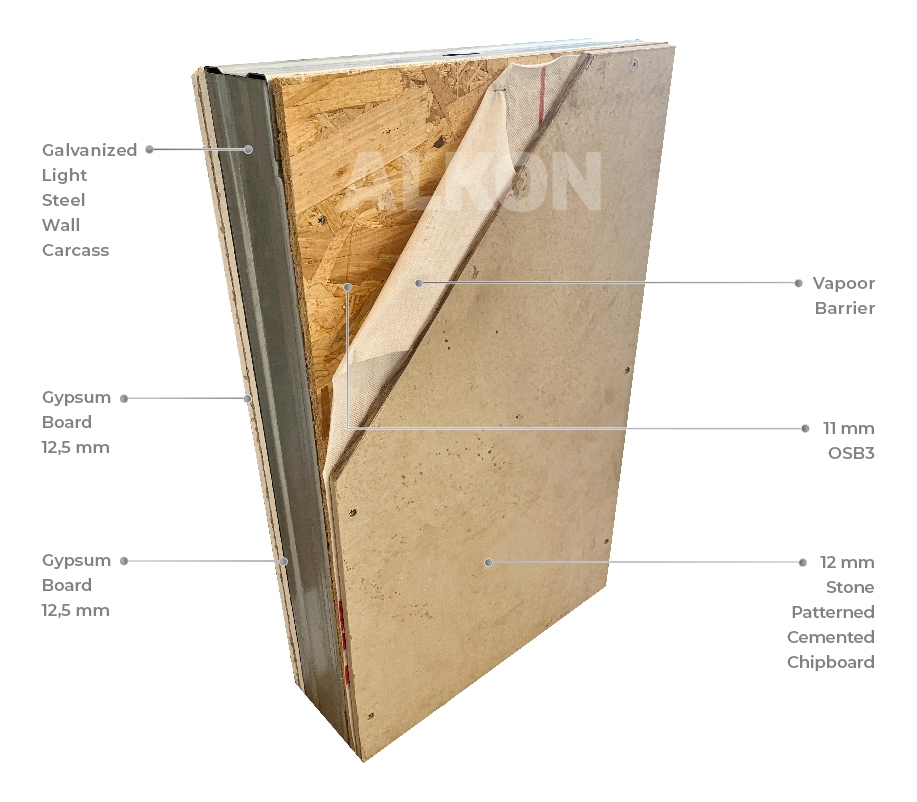

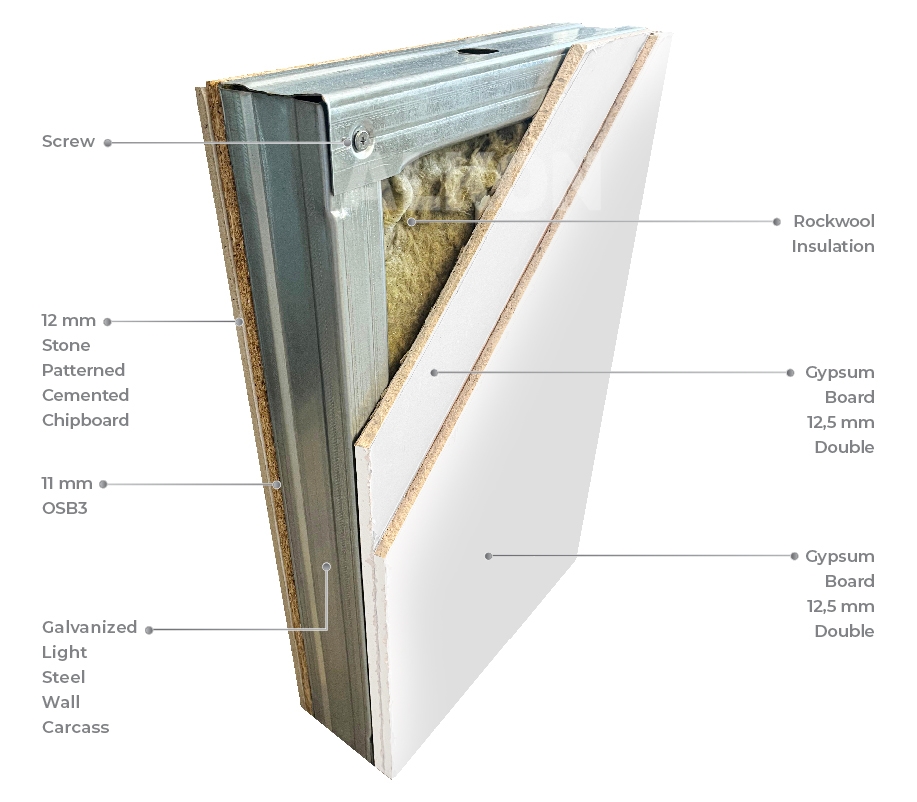

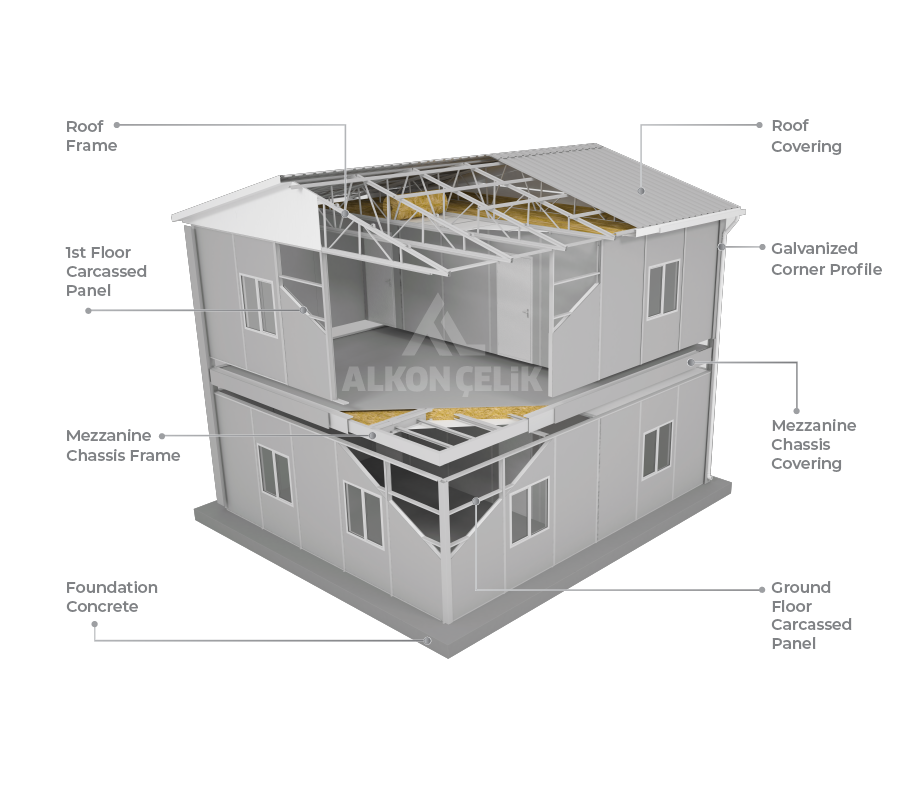

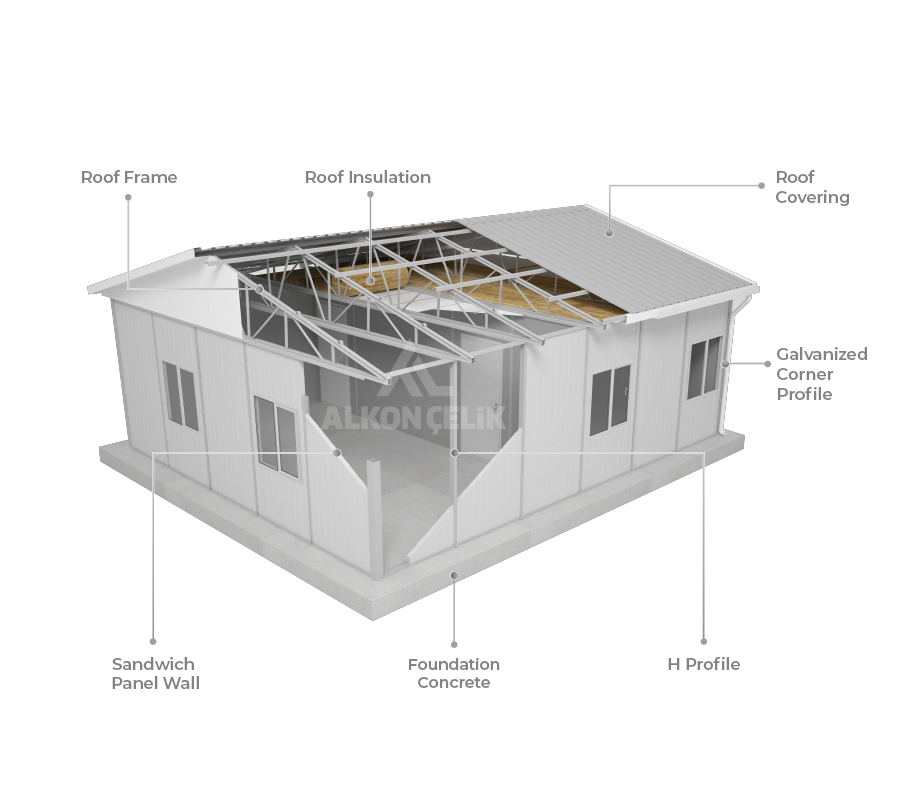

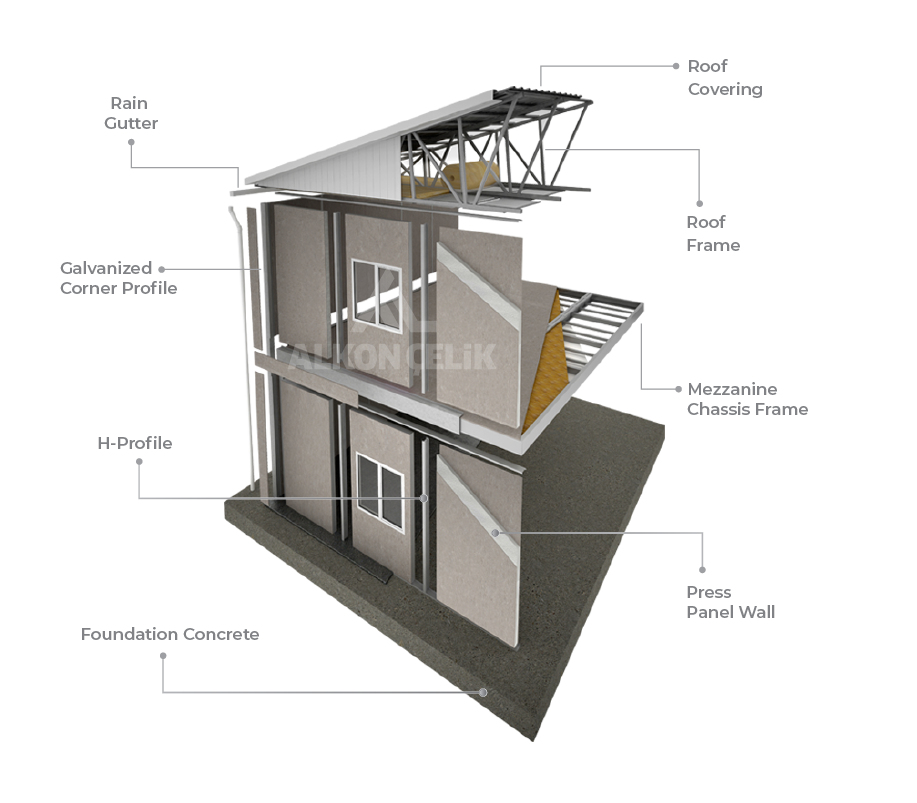

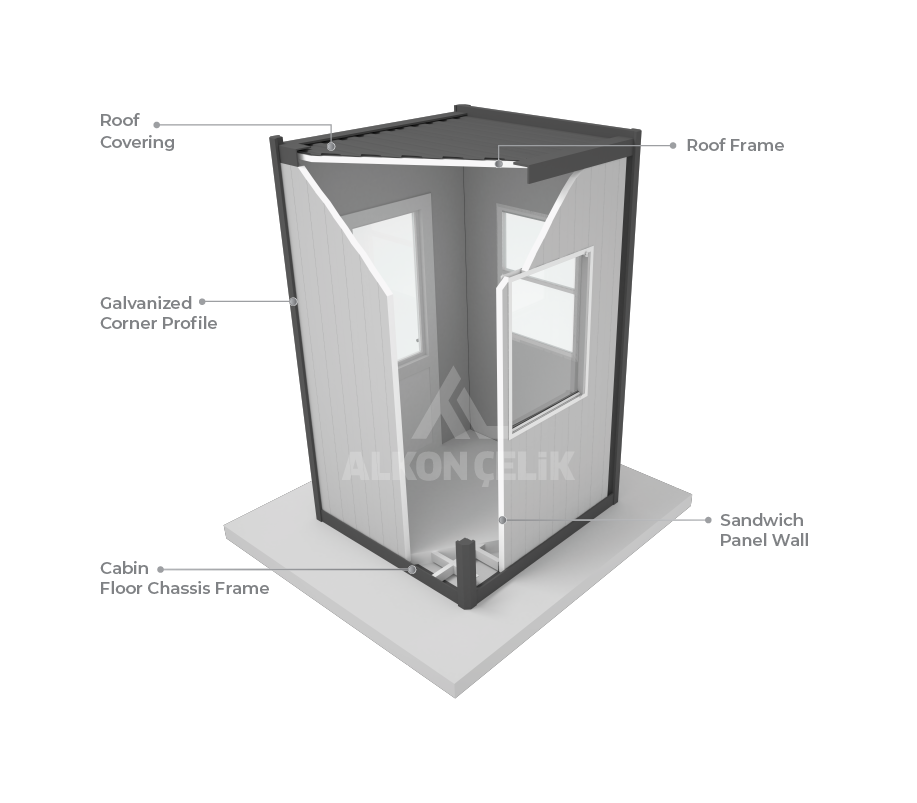

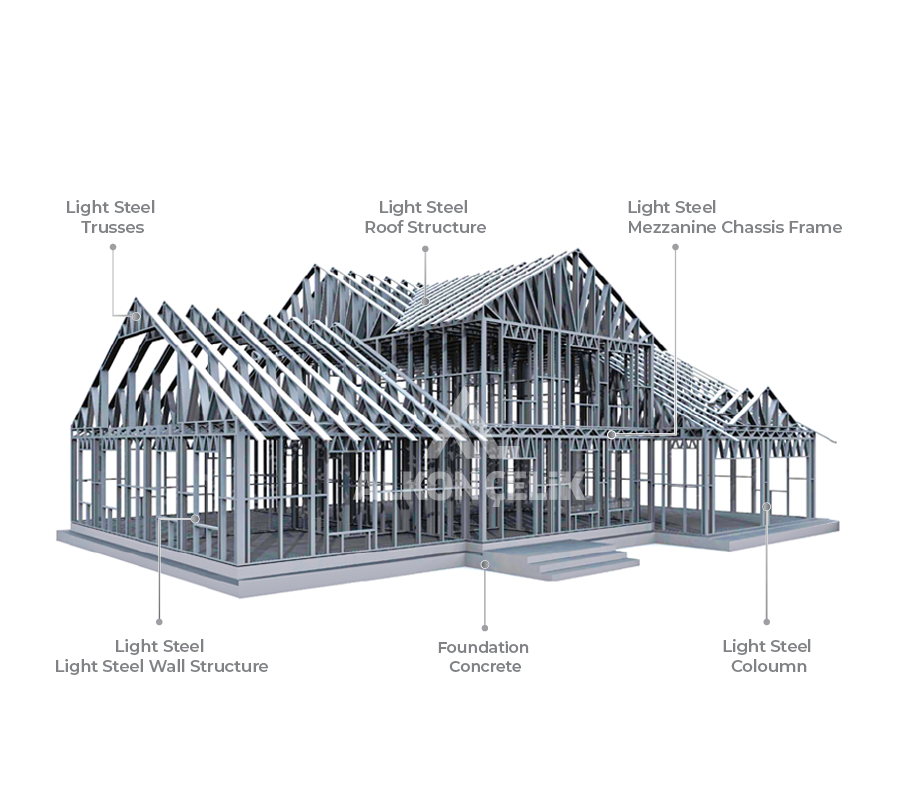

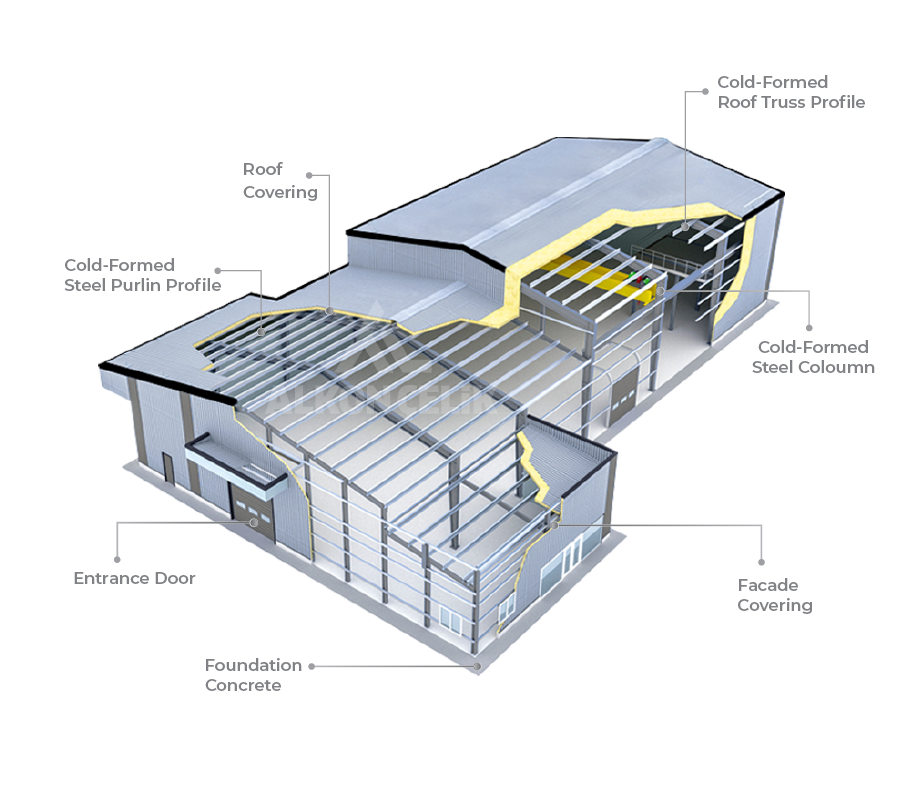

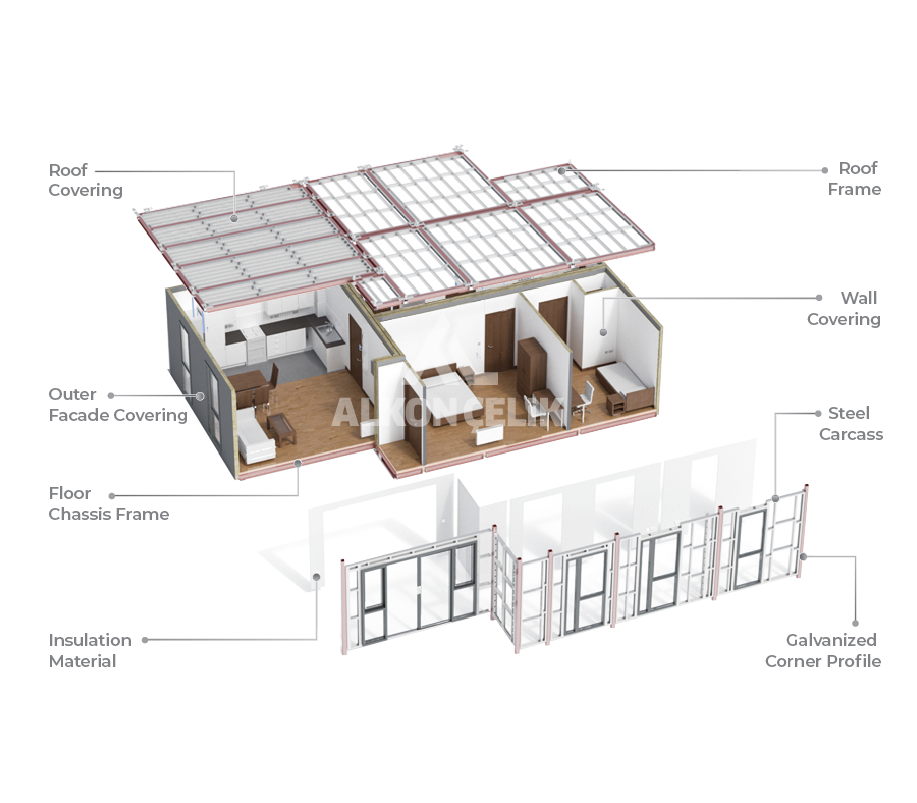

ANSWER: They are ready-made structures where all wall carcass, insulation and covering materials are prepared in the factory environment, transported to the site where they will be assembled. Light steel profiles are used as the main carrier system, materials that are resistant to natural conditions on exterior and interior facades, and insulation materials with high insulation value are used.

QUESTION: How are the light gauge steel (LGS) or prefabricated building construction processes?

ANSWER: The light gauge steel (LGS) and prefabricated building plan are prepared in line with the demands of our customers, the climatic conditions of the region where it will be installed and the materials to be used according to the choice of our customers are determined. The prepared plan and technical details are clarified and a contract is made. Production is completed in the process specified in the contract, the building is shipped, assembly is done by our professional teams.

QUESTION: Who gets the license for light gauge steel (LGS) or prefabricated buildings?

ANSWER: Our customers obtain the licenses for light gauge steel (LGS) buildings. For the license, an engineering office (architectural project, electrical project, plumbing project, mechanical plan) is prepared in the region where the building will be established, and the legal permit application is made by your architect.

QUESTION: How many floors can light gauge steel (LGS) buildings or prefabricated buildings be built?

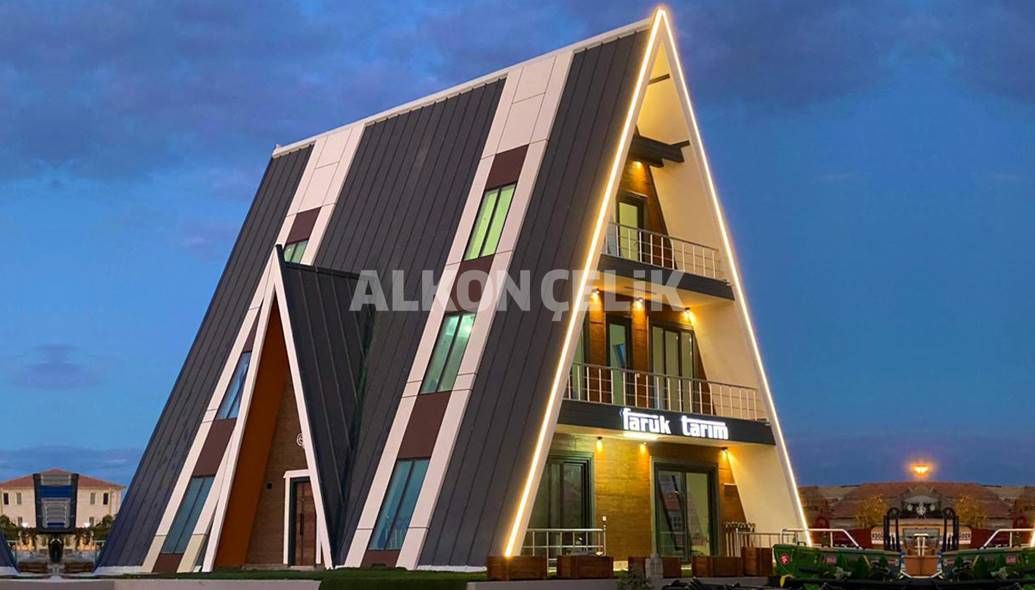

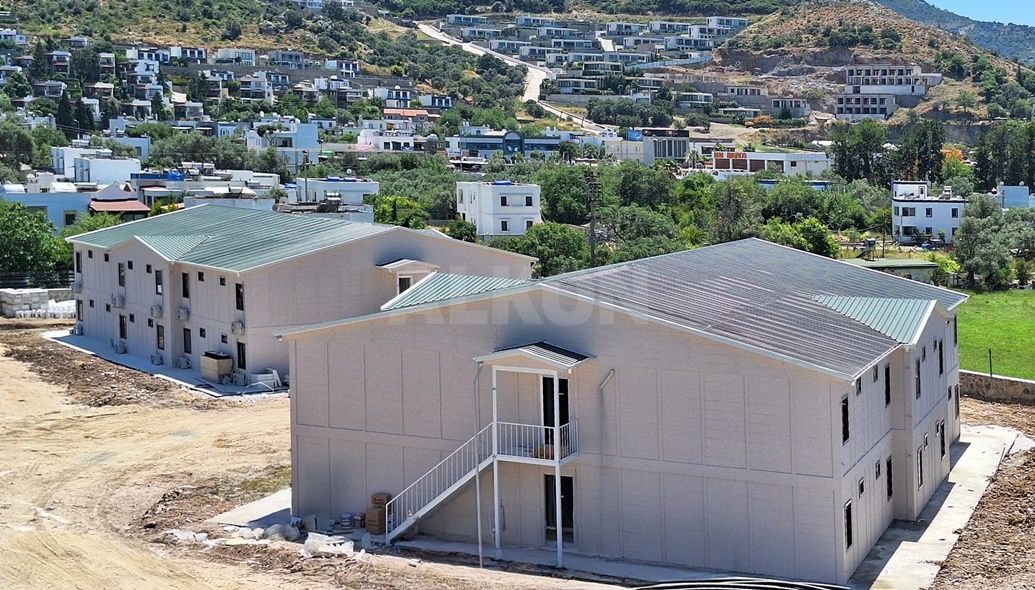

ANSWER: It is usually built with one, two or three floors. Even 4 floors are available. Special optional floor requests are evaluated.

QUESTION: Can our projects convert to light gauge steel (LGS) or prefabricated type buildings?

ANSWER: Since light gauge steel (LGS) buildings consist of carcassed wall modules, we can work close to your projects. It is similar for prefabricated buildings.

QUESTION: Are light gauge steel (LGS) houses or prefabricated built only for summer house or second house purposes?

ANSWER: Light gauge steel (LGS) buildings are alternative to concrete buildings. Since the production of light gauge steel (LGS) houses is made considering the regional climatic conditions, you can easily use them in 4 seasons. Prefabricated buildings can be used all year too.

QUESTION: Can tile ceramic applications be applied to the walls of light gauge steel (LGS) or prefabricated buildings?

ANSWER: It can be done. The only thing that needs to be considered is that adhesives with elastic properties should be used.

QUESTION: Painting etc. on the walls. can it be hung?

ANSWER: You can hang tables by screwing on the walls, but heavy accessories should be screwed to the carrier profiles.

QUESTION: Can we do the painting process ourselves in light gauge steel (LGS) or prefabricated buildings?

ANSWER: We do not recommend it at the first painting for light gauge steel (LGS) buildings or prefabricated buildings as the joint elements or outer covering joints are siliconized before the painting process.

QUESTION: How can we find out the technical properties of the materials you use?

ANSWER: You can get detailed information from our website or by contacting our office.

QUESTION: What is included in the prices given for light gauge steel (LGS) or prefabricated buildings?

ANSWER: Light gauge steel (LGS) structures or prefabricated building structures are delivered to advanced rough. Light gauge steel (LGS) building's wall carcasses, wall coverings, insulation, connection elements, ceiling, ceiling insulation and roofing material, supply of exterior and interior doors, windows, transoms and glasses, interior and exterior paint, electrical and water installation in the building, installing lamps, sockets, vitrified the supply of fixtures are included.

Note: Since the tile and ceramic processes in light gauge steel (LGS) or prefabricated buildings belong to the buyer, the installation of sanitary ware is done by the buyer.

QUESTION: What should the customer do in light gauge steel (LGS) or prefabricated buildings?

ANSWER: Making the ground concrete and all kinds of excavation, landscaping, floor and wall coverings (screed, ceramic, tile, etc.), light gauge steel (LGS) or prefabricated building external connections (electricity, waste water, clean water), permits and license procedures to be obtained from the municipality, heating and cooling installations (such as radiators, air conditioners etc.), accommodation and catering costs of our assembly team in installations outside of Istanbul in Turkey, transportation and transportation insurance of the materials belong to our customer.

Note: Assembly out of Turkey is not included in scope. If needed, supervisor can be send to the site. In this case visa, return plane tickets, transfer two directions between airport and site, accommodation, catering, security and health service of supervisor’s will be under responsibility of customer.

QUESTION: Can light gauge steel (LGS) or prefabricated buildings produce different insulation solutions for cold regions?

ANSWER: Insulating materials on the outer walls can change and the wall thickness is increased when necessary. Sheathing application can also be made to the exterior if requested.

QUESTION: What is the approximate usage period of light gauge steel (LGS) or prefabricated buildings?

ANSWER: Therefore the life of the materials used in light gauge steel (LGS) buildings, a minimum life of 70–75 years is given for the buildings. It is about 50-55 years for prefabricated buildings. To use building in a healthy way, the maintenance has to be done periodically.

QUESTION: How many days are the delivery times of light gauge steel (LGS) buildings.

ANSWER: Depending on the production schedule of an average 100m² single-storey building, the production takes around 20–25 days and the assembly process takes around 30–45 days.

QUESTION: How is the payment for light gauge steel (LGS) buildings?

ANSWER: Advance payment is necessary to start the production period. 40% cash is received to start work at the contract stage, and the remaining balance is collected at the production stage before loading. Documentary payment and term payment alternatives can be negotiated mutually.

QUESTION: With which vehicles can light gauge steel (LGS) or prefabricated buildings be transported?

ANSWER: Light gauge steel (LGS) or prefabricated structures can be transported by truck, DC or HC, ship, train or cargo plane.

QUESTION: Is there any shaking on the ground of the upper floors in multi–storey buildings?

ANSWER: Static calculations of light gauge steel (LGS) buildings are made according to certain standards and regulations (TS 648, TS 498, TS 11 372). Production takes place in line with these values. Therefore, there is a permissible amount of deflection in the intermediate floors. Intermediate section determinations are made by calculating an average of 250kg/m2 intermediate load in houses.

QUESTION: Can light gauge steel (LGS) or prefabricated structures be moved again after they are installed?

ANSWER: Light gauge steel (LGS) structures can be dismantled and moved to another place upon request. Since there will be disassembly assembly cost and 10% material deformation, additional material will be required. It is possible to make modifications in light gauge steel (LGS) or prefabricated buildings, if requested.

QUESTION: Do the materials used in light gauge steel (LGS) or prefabricated buildings have any harm to the environment and human health?

ANSWER: Light gauge steel (LGS) or prefabricated building materials do not contain any substances harmful to the environment and people. All materials used are produced in accordance with TSE/EN conditions.

QUESTION: Are light gauge steel (LGS) or prefabricated buildings earthquake resistant?

ANSWER: Light gauge steel (LGS) or prefabricated structures are produced considering the 1st degree earthquake zones. Since the building elements are connected to each other with screws and bolts, the collapse of the structure due to flexing during an earthquake is prevented.

QUESTION: Can I choose the paint colour of the light gauge steel (LGS) or prefabricated building myself? Or is there a fixed colour?

ANSWER: You can choose the colour you want from the paint chart we offer.

QUESTION: How are light gauge steel (LGS) or prefabricated structures mounted on the ground?

ANSWER: Light gauge steel (LGS) or prefabricated structures are mounted on the concrete prepared by our customers with the help of steel dowels. Thus, the building is fixed to the ground concrete.

QUESTION: Where can I see the light gauge steel (LGS) and prefabricated sample buildings?

ANSWER: You may see light gauge steel (LGS) sample building at our factory located in Dilovası, Kocaeli, TR. You also may see prefabricated sample building at our showroom located in Esenyali–Pendik, Istanbul.

Prefabricated Constructions

Prefabricated Constructions

Containers

Containers

Cabins

Cabins

Industrial Steel Constructions

Industrial Steel Constructions

Construction Profiles

Construction Profiles

Modular Constructions

Modular Constructions

Camp Constructions

Camp Constructions